Application engineering

Application engineering

CMZ application engineering department provides consultative advice to our customers so that our CNC lathes adapt to production needs. CMZ lathes are present in a wide range of productive sectors with different production levels, geometries and materials. For this reason, the application engineering developed by CMZ is a key throughout the process. We analyse carefully each client's productive needs in order to design the best solution. The usual protocol is the following:

- Definition and development of processes to follow.

- Choice of CNC lathe best suited to meet the needs

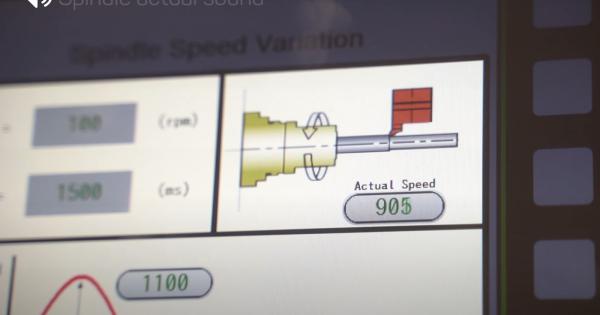

- Cycle time estimates.

Training, CAD / CAM programming, automation ... CMZ´s commitment is permanent and we offer support throughout the life cycle of our lathes.

Your search did not match any results

APPLICATION ENGINEERING

ADDED VALUE FOR YOUR LATHE

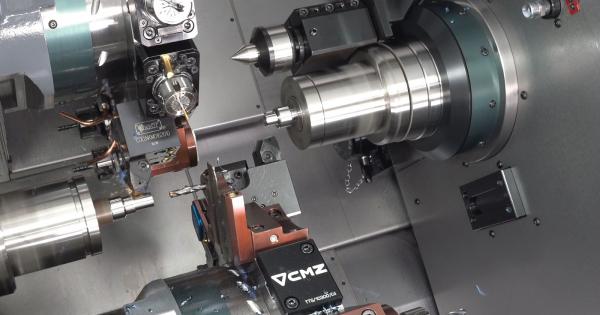

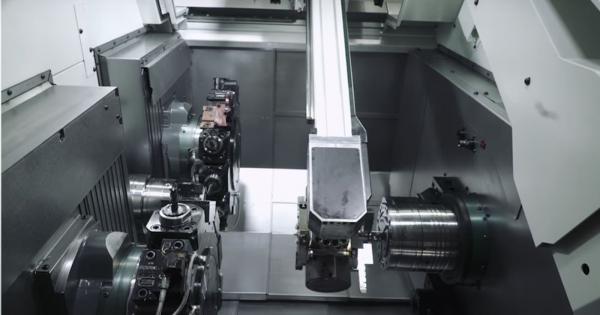

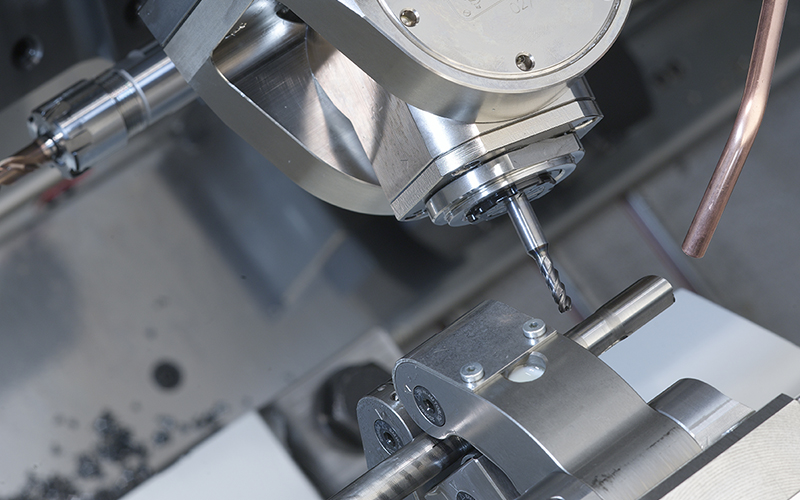

Our applications engineering department may be your best ally for optimising your production processes and improving machining times. A team that has a key function in the buying process, because with its capacity to adapt to different market demands, it can provide the solution that best suits the production needs of each customer. This approach provides added value to the buying process for people who are looking for more than just a CNC lathe.

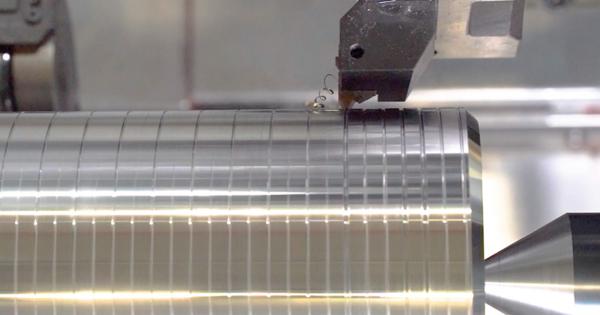

Each customer comes with a new challenge, and our job is to find a solution to their needs”. That is how Ainhoa de la Iglesia, Applications Manager at CMZ, summarises one of the department’s main functions. Every day they receive requests for new projects and technical consultations and our team acts as support for the sales department in these cases. For that purpose, first of all, the customer submits the drawings and technical requirements for the project. After analysing the feasibility of the project, the most appropriate configuration for the machine is chosen and a time study is conducted. The time study is the basis for the viability of the process and is presented, together with the quote, to the end customer.

For that purpose, first of all, the customer submits the drawings and technical requirements for the project. After analysing the feasibility of the project, the most appropriate configuration for the machine is chosen and a time study is conducted. The time study is the basis for the viability of the process and is presented, together with the quote, to the end customer.

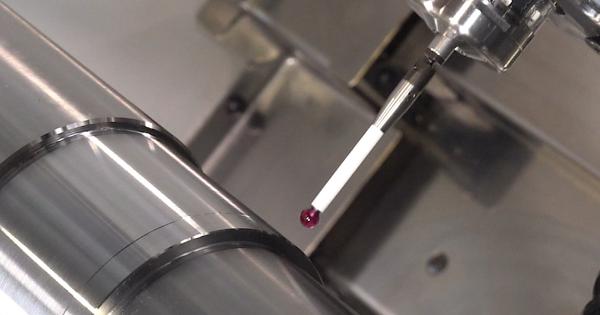

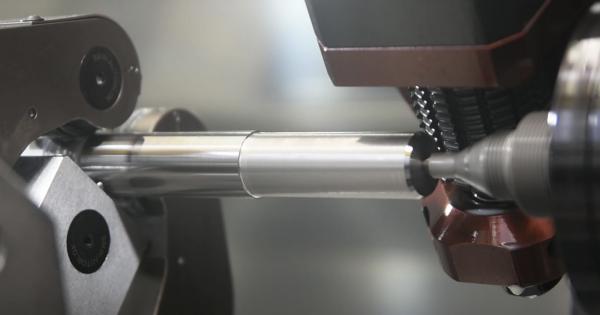

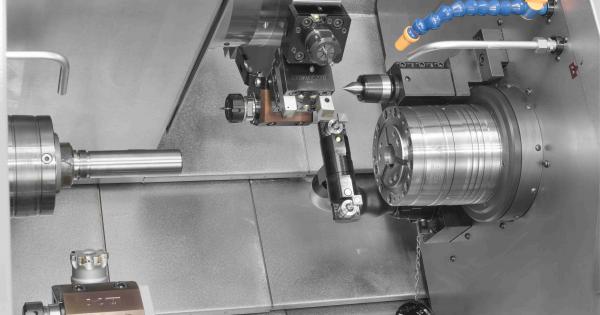

Communication with the customer is ongoing throughout the process, solving any issues and providing feedback on the progress of the project. “While the lathe is being manufactured, our team is responsible for finalising the last preparations so that when assembly is finished we can have everything ready to start with the application” says Ainhoa.

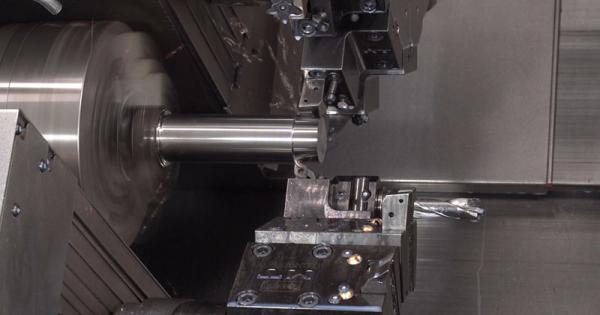

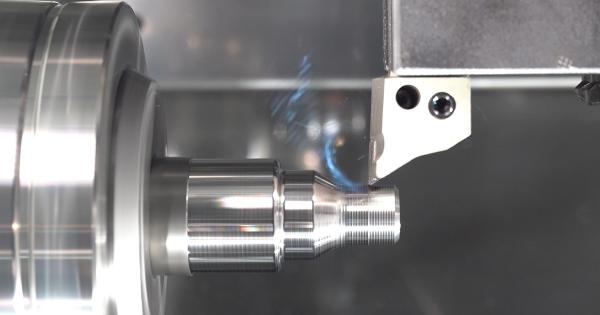

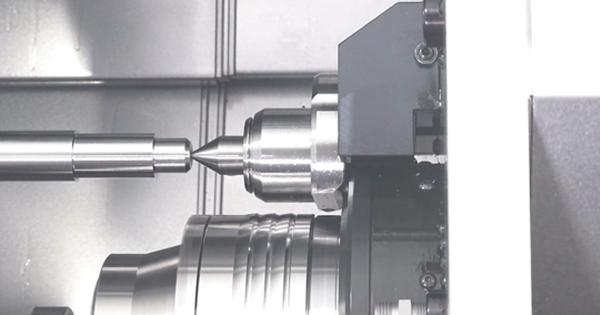

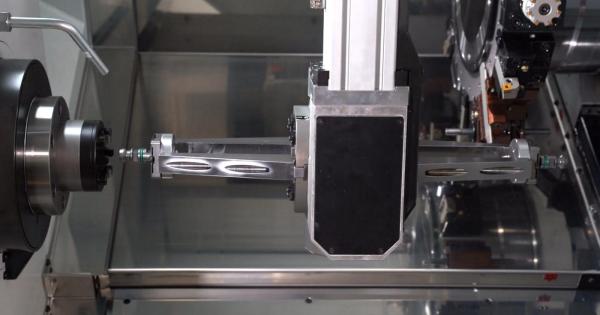

To ensure the quality of the machines, our NEOPREC plant has a reception area with strict temperature control and 800 m² of clean room to ISO 8 standard with latest generation three-dimensional machines. At that moment, the applications engineers prepare what is needed in the machine and validate the programming, machining parts according to the previously specified requirements. On several occasions, the customer travels to our facilities to validate the process in situ.

« Our job is to find a solution tailored to the needs of the customer »

Each project is different. We cover needs such as capacity studies, validation of specially prepared accessories for the customer’s process and even automation.

Direct collaboration with the customer is a key factor in the success of projects of this type. Our team is 100% involved in our customers’ production processes, in a variety of industrial sectors.

Most of the projects undertaken in the applications department are confidential, but work is done in very different sectors like defence, automotive, capital goods and renewable energies.

But, what added value does our applications department bring to the purchase of a CMZ lathe? The answer is easy. The market is increasingly tending to commit to this type of project where the customer acquires more than just the machine.

We have a team in continuous training, able to provide consultancy advice whatever the production needs If you are seeking to optimise your process productive and reducing machining time, our applications department may be your best ally.

DO YOU NEED HELP WITH AN APPLICATION?

Our applications department can analyse in detail the process to be carried out and offer you a part study helping you to reduce cycle times.