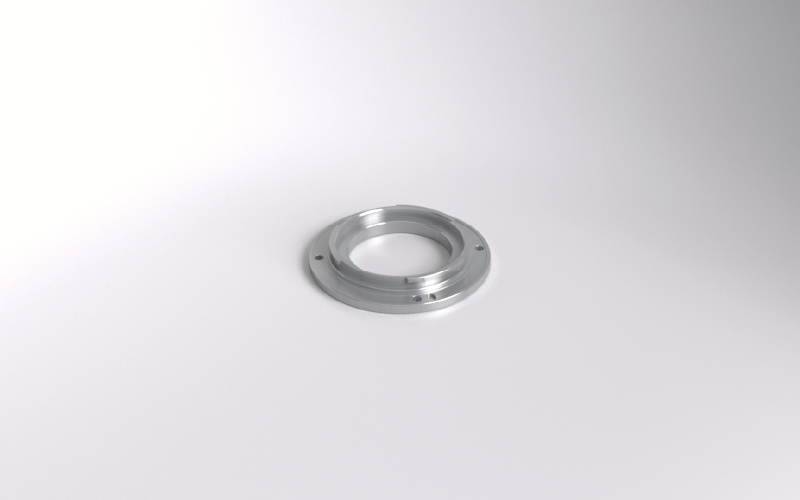

Photography cameras are highly appreciated in our society. Since their beginnings, they have certainly been a great ally in immortalising the most important moments of our lives: that trip, that special birthday, meals and long-lasting friendships...From the tripod to the selfie, from black and white to the purest colour, these devices have been with us since time immemorial (since 1816, to be precise). In this article, we explain how certain camera lens parts are produced on a CNC lathe.

Nowadays, it is impossible to imagine life without the opportunity to immortalise the moment using a photography camera. That is largely possible thanks to the companies and manufacturers who dedicate their activity to the manufacture of various parts: the camera body, the sensor, the screen, lens mounts... Over time, these elements have been adapting to the new technologies and market needs and as a result, quality standards have increased exponentially.

For that reason, the manufacture of components like the parts for connecting the lens to the body of the camera requires machinery that can deliver accuracy and high repeatability. A highly precise CNC lathe is needed, with short cycle times to ensure the product is competitive in the market. Deciding which machinery to choose is a hard task, because there are many possible configurations and technical specifications, but below we show the best CNC lathe for manufacturing lens mounts.

If you are looking for a lathe that guarantees maximum quality in the manufacture of lens mounts, the TTL Series could be your best ally. This CNC turning centre for high production can work with very high volumes, ensuring delivery times and levels of precision at all times. One of the characteristics of particular interest in the TTL Series is that the machine is beltless and has 8 integrated motors that increase accuracy with each turn, because transmission is direct.

More specifically, the best option for manufacturing lens mounts is a TTL-66-66-T1Y-T2Y. That is because of the speed at which it operates and the diameter of the part, as well as the fact that to make the holes and connection tabs, a driven tool is needed. This CNC turning centre is fitted with high power synchronous motors that can halve acceleration time, making the TTL Series the best ally for producing camera lens parts. Smile!