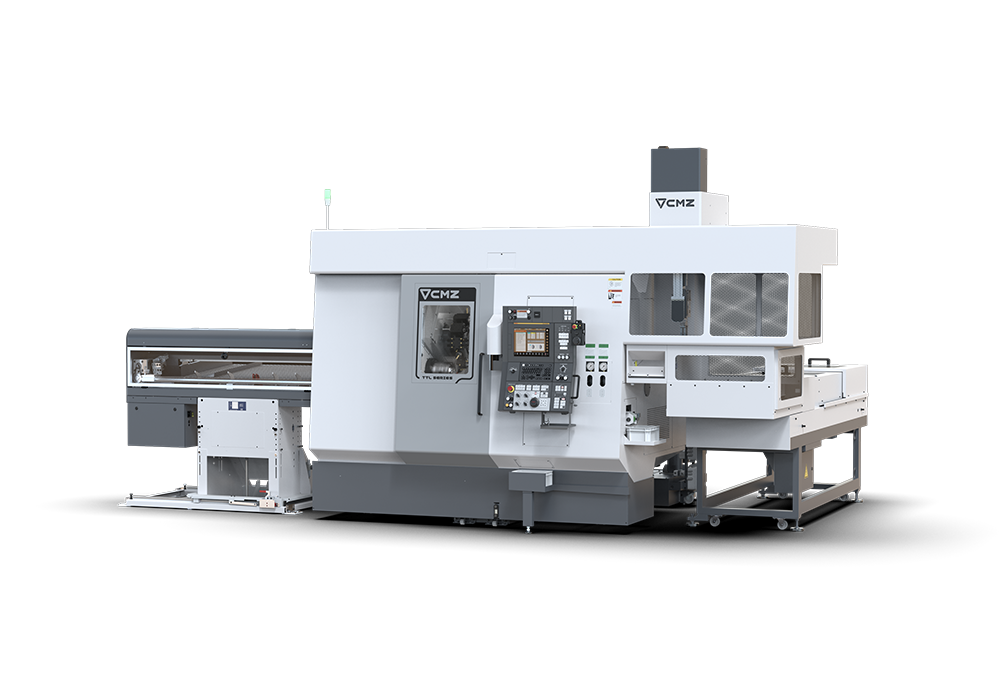

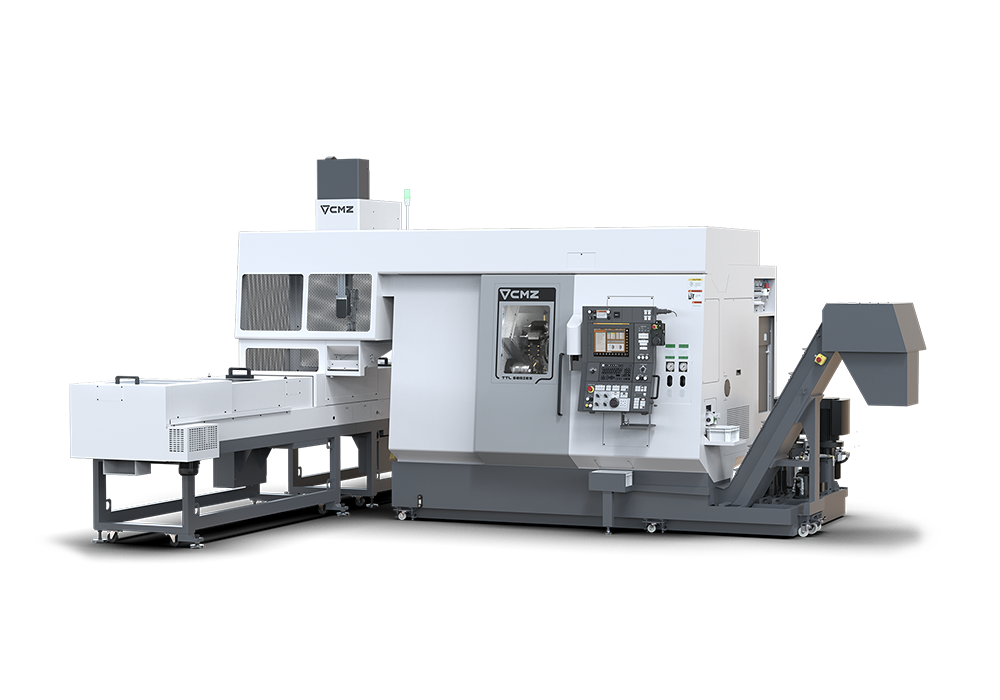

Do you want to automate your production process in order to reduce loading and unloading downtime? Thanks to our range of gantry loaders, we offer different possibilities for CNC automation. GL6, GL20, GL 100... there is a type of gantry loader for each production process and if there isn't one, we adapt it. In addition, we have designed different workstockers. Programming this type of process is very simple. The software is very intuitive and has been developed so that the user has to input the minimum amount of information, making the cycle work in all cases. Compared to anthropomorphic robots, our gantry loaders are cheaper, more ergonomic, much easier to program and are much faster. Whether you work with billets or shafts, our gantry range can be your best ally. Workstocker for billets, for shafts, special solutions, increased pallet capacity... We are able to find the automation solution that your process needs.

Our entire range of gantry loaders are easy to program and operate. We have developed a conversational programming system for the robot that allows an agile part change. Programming is very simple since the software minimises the amount of information to be entered by the user, making the cycle work in all cases. With our gantry loaders material loading and component unloading times can be effortlessly slashed, improving the overall performance of the CNC lathe.

In this video we show you that it can be prepared to change from one short run to another in under 5 minutes. This video is a recording from one of CMZ's turning facilities in the recently renovated Precitor (Elorrio). Here you can see how Sergio, part of the team of operators who usually prepares one of our 12 CNC lathes, changes a TD-30-YS-800 + GL100 from one short run to another. You will see how the additional time for preparing the Robot and starting it in automatic mode is only 4 minutes and 29 seconds. In this case, the machine is making a part with diameter 171 mm and weight 9 kg and we prepare it to make another part, this time 236 mm in diameter and weighing 7 kg.

CATALOGUE AUTOMATION SOLUTIONS

Catalogue of Automation Solutions. Get to know in depth all the possibilities and technical characteristics of our Gantry range.