Is there anything more relative than time? Something which originated with the study of astronomy and has managed to unify the entire planet with the same concept of time. The watch crown is a small part on the side of the watch that is used to wind the watch or change the time or date. Without the crown, the phrase "not knowing what time it is" would make sense and therefore, producing these crowns is in the hands of the most precise manufacturers in the world.

This central European country is known for precision in the watch-making industry. The mechanisms that make a good watch operate so accurately are perfectly machined to provide watch wearers with the exact time. But, what happens if you have to reset the time? This is where the watch crown comes into play. The making of watch crowns is also left to producers (not necessarily in Switzerland) with high standards of quality. This small part with an elongated body is positioned next to the 3, that is, in the first quarter on the right side of the watch and is used to wind the watch or change the time or date, being screwed into the winding stem or sometimes into the watch case.

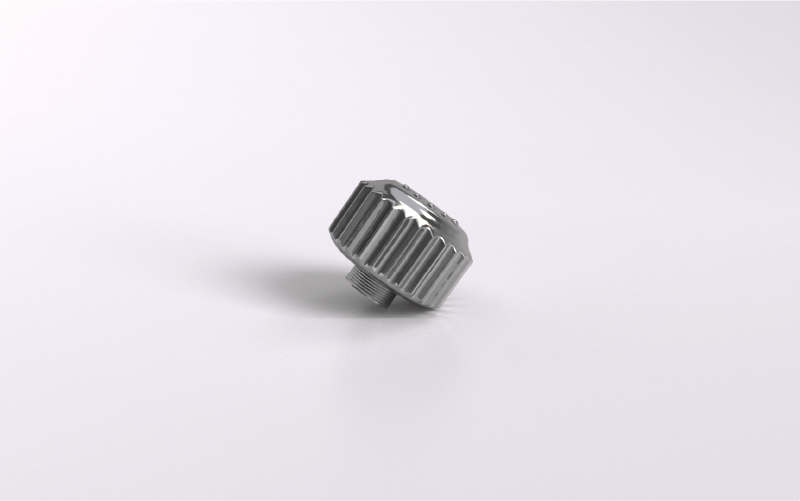

Watch crowns can be made from a variety of materials, depending on the characteristics of the brand. Normally, they are usually made of chromed or plated brass, but that depends on the manufacturer. Sometimes they also have a ribbed surface, but there are different types of watch crowns and they are not always the same shape. Even so, despite its seemingly aesthetic function, it fulfils a very important mechanical function for the correct operation of all types of watches.

When discussing the manufacture of parts for watchmaking, we have to talk about precision. Although it may seem like a metaphor, each minute counts in the process of making watch crowns, and for that reason, it is important to have machinery that ensures short cycle times and accurate results. For that purpose, the fixed headstock lathe for high precision machining in the TTS series can become your best ally in the workshop.

Specifically, the model TTS-38-38-T1Y is a sure bet for ensuring the correct manufacture of high-quality watch crowns. This lathe has two turrets, but its compact size makes it possible to machine large batch runs of small parts with high precision. It also has a driven tool for machining the ridges. All the precision and power concentrated in a compact machine ideal for manufacturing parts for the watchmaking industry. Now ask yourself, what time is it?