Different types of machines are available on the market that can help you achieve the desired results in precision machining. The lathe is an ideal machine when very tight tolerances are involved, because it can perform operations with micron-level precision. CMZ, with their exceptional pedigree and experience over a number of years, can offer a wide range of CNC lathes have developed the turning process in to a fine art from where the tightest of tolerance can be achieved and maintained for life span of the machine. The key to CMZ achieving these results and understanding our customer needs are as follows:

In an industry like the machine tools industry, precision is key and so each micron counts. The use of lathes for precision machining is widespread and a variety of industries attach increasing importance to purchasing high precision lathes for their work. With the technical capabilities of precision lathes will be key to achieving the targets that are set. It is also very important that the machine can work with different materials guaranteeing part repeatability.

Having a range of machinery for manufacturing parts with tightest of tolerance is essential for these companies. We at CMZ understand that every micron is important when precision machining and our lathes will help you achieve this with the aid of highly skilled operator and programmers. It is important that the materials used are of a specific specification to active the results you want continuously.

A key point for ensuring the machine can produce high quality parts that meet our and the clients standards using precision machine is the assembly process. Integral control of the process is a key element, because the more control the manufacturer has over the manufacturing process, the more knowledge it will have over the points for improvement. In addition, by insourcing most of the processes, more is invested in improving the quality of the product, leading to machines that ensure high levels of precision throughout their service life.

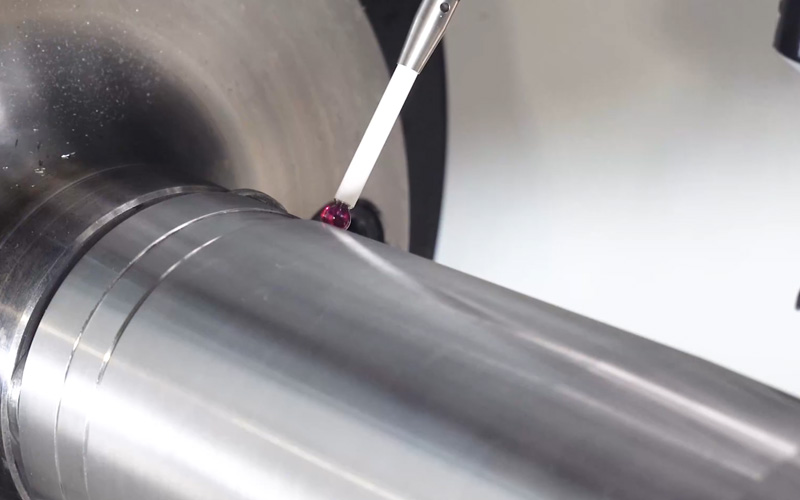

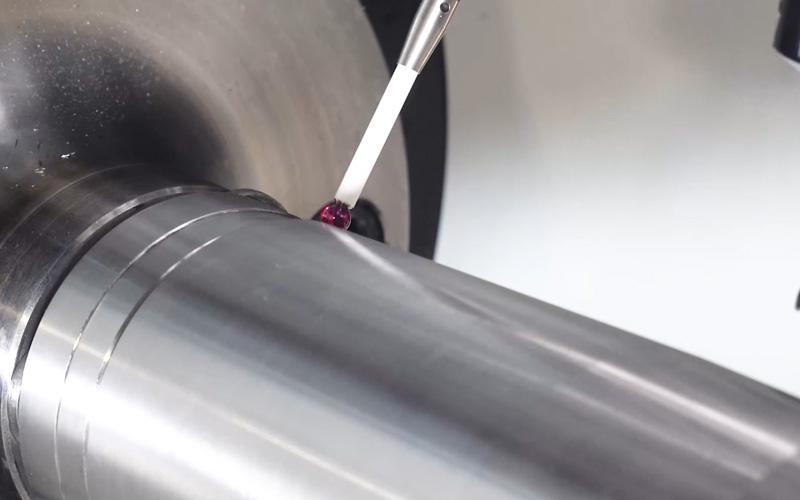

Because of this, the lathe assembly process is a key point for ensuring production within very tight tolerances. To that end, it is important to pay careful attention to each detail in the value chain. For example, to manufacture our machines we pay careful attention to the alignment of the spindles to ensure the nuts turn smoothly, avoiding play. Play can often be the cause of a considerable reduction in the precision of the machining over time.

At CMZ, we manufacture over 80% of the components for our lathes. One of the benefits of manufacturing 80% is that this enables us to guarantee the durability of the machines and ensure high levels of precision machining throughout their lifespan as well as supporting European manufacturing. In addition, because these components are not imported, we save on customs duties and invest in high quality components, actively collaborating with world-leading brands.