Are you looking to machine large parts? Are you unsure about which large lathe is best suited to your needs? In the face of such an important decision like this one, and the infinite range of options on the market, it is of the utmost importance to compare and note down the pros and cons of each option. There is a wide variety of brands and models available now which you have to know about before taking such an important decision: Doosan Puma 4100, Doosan Puma 5100, CMZ TD Z2200-Z3200, Mazak Quick Turn 450…

When discussing lathes for machining large parts, the market offer varies widely. Doosan Puma 4100, Doosan Puma 5100, CMZ TD Z2200-Z3200, Mazak Quick Turn 450… All of these lathes have been specially designed for machining large parts, but they need to be compared to find the best option.

The wide variety of parts machined on this type of lathe, for sectors that are as demanding as, for example, the energy industry, means that the technical characteristics of the lathes meet the maximum standards of quality and precision. For that reason, it is important to conduct an exhaustive analysis of the different options available on the market.

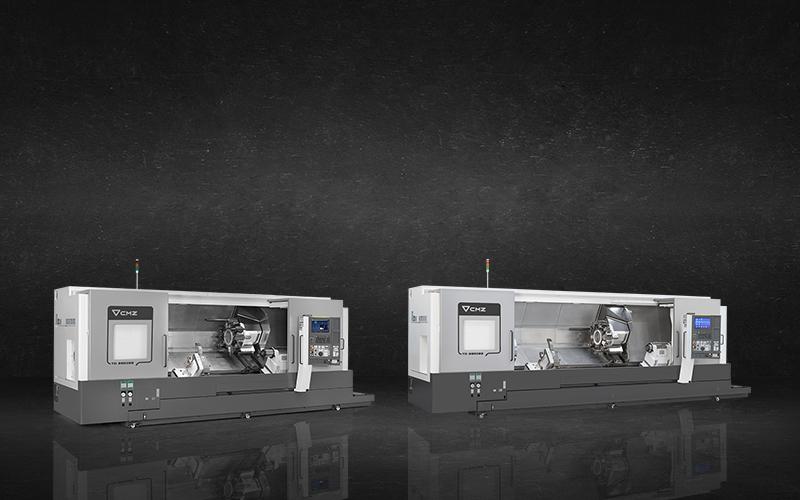

Exactly that, size doesn't matter for the large CMZ lathes. With their beds of more than 2 or 3 metres between the chuck and tailstock, large parts can be machined. "Large DOESN'T mean slow", that is the best description for the lathes in CMZ's Z2200-Z3200 range, because thanks to their turret with integrated 12,000 rpm, 105 Nm and 13 kW motor, they can handle any part. This is a good option if you need to machine large parts and long shafts. And furthermore, drilling holes deeper than 42 times the diameter of the lathe is possible in these large machines.

Another of the advantages of this model compared to those of our competitors is that they permit the option of a steady rest. The clamp prevents the appearance of vibrations when machining very long, slim shafts, which gives the TD Z2200-Z3200 model an advantage as regards the versatility and type of parts that can be worked with. In addition, the integrated spindles have the option of incorporating a double pneumatic chuck with a through bore of up to 192 mm in diameter.

CMZ, a machine tools manufacturer for over 75 years, is committed to European production, manufacturing more than 80% of the components for its machines in-house. In this way, we can produce large lathes with over 20 years of useful life, which are key in the production of large components for a variety of industrial sectors. If you are looking for a lathe for machining large parts, and you are overwhelmed by the wide variety of models on the market, remember that CMZ's TD Z2200-Z3200 model is a very competitive option both in terms of technical performance and price.