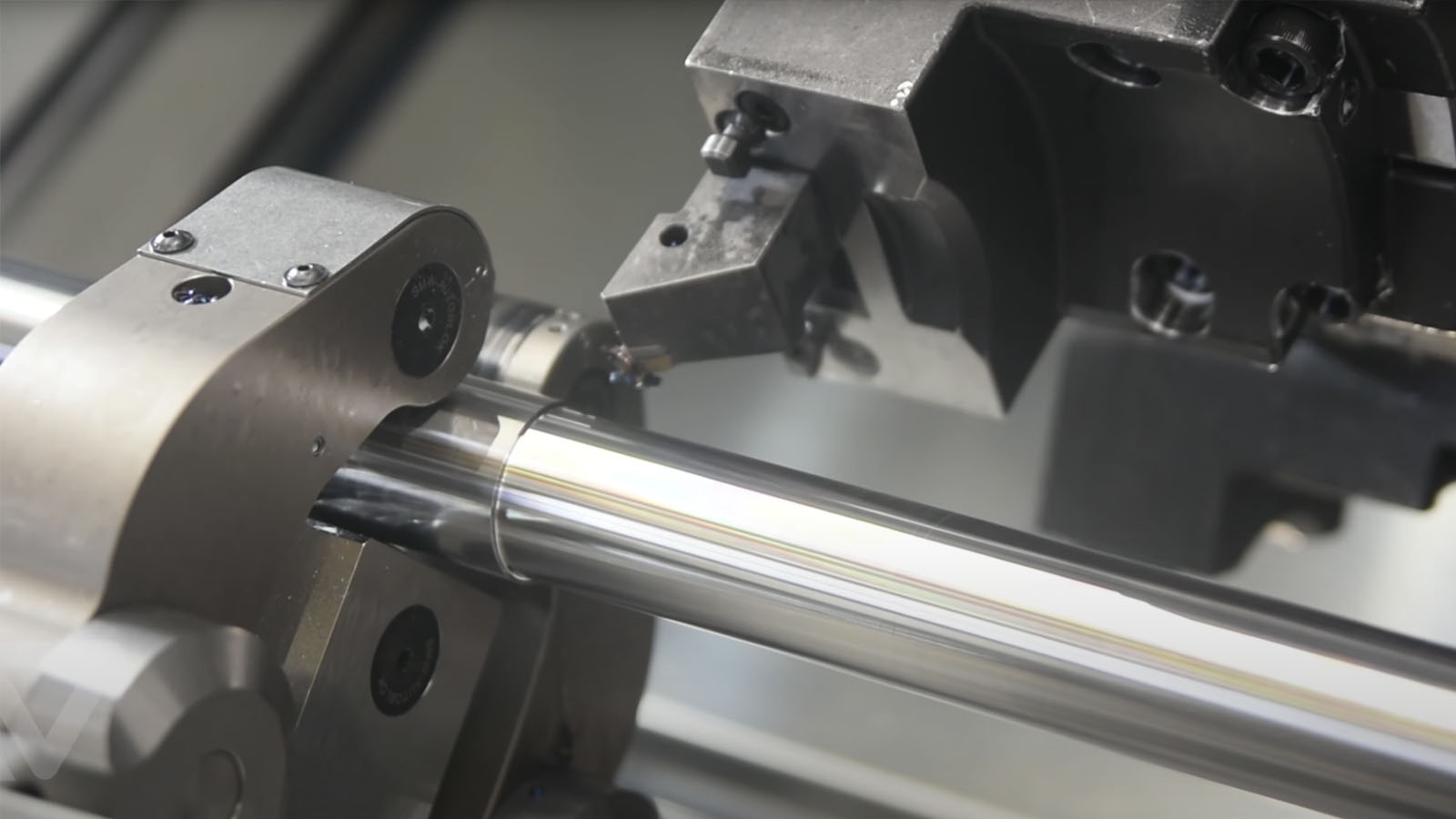

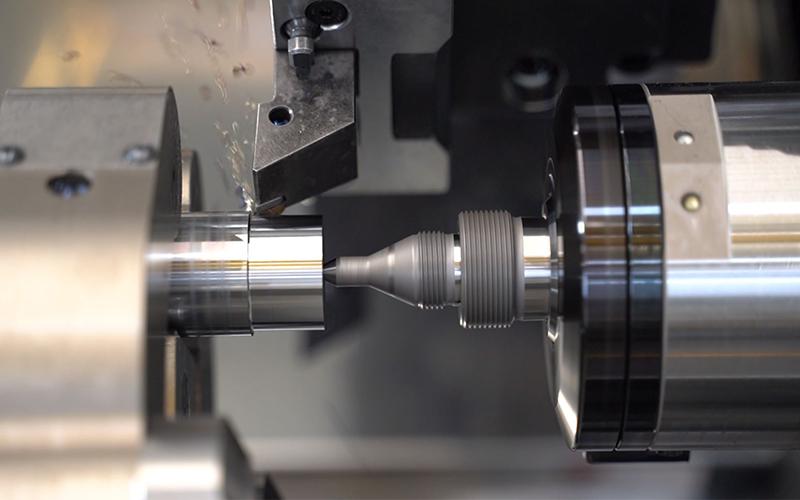

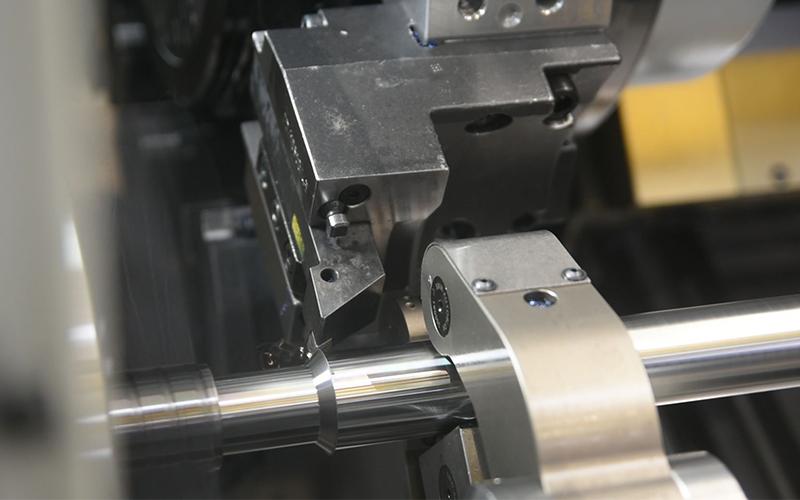

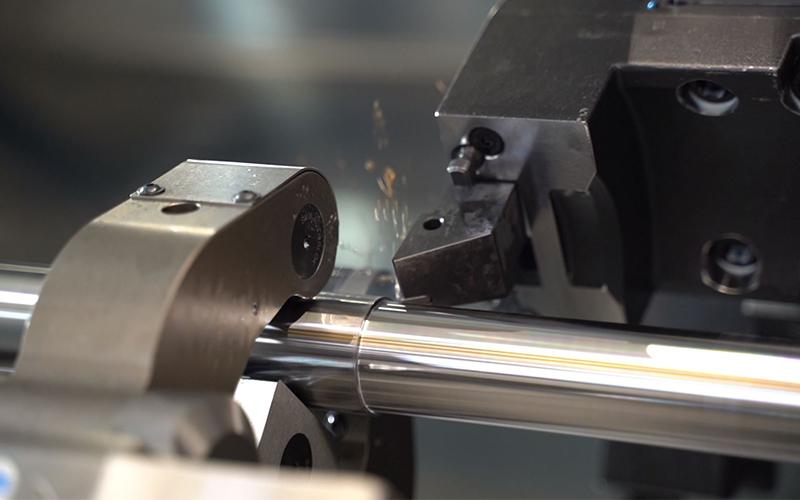

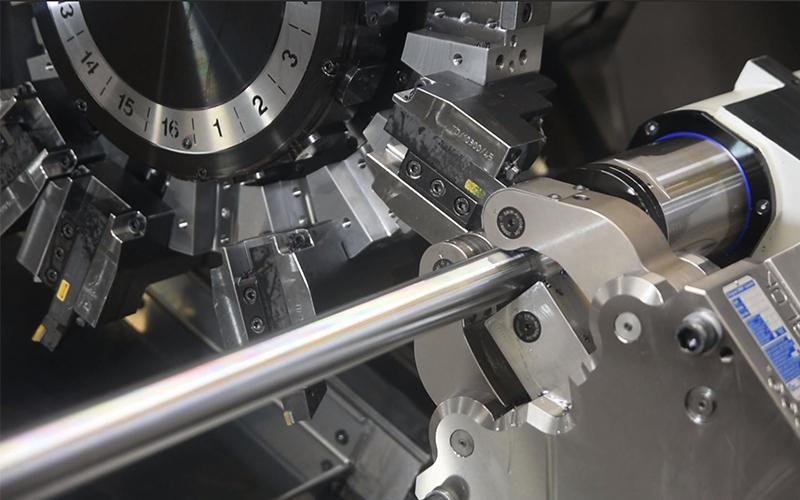

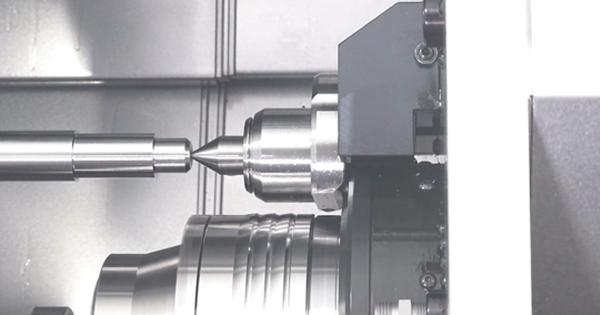

Our TD series of lathes are ideal to machine this type of component. When equipped with a travelling steady accuracy and surface finish can be maintained along the entire length of long and slender diameters, supporting shafts that would be next to impossible to turn without one.

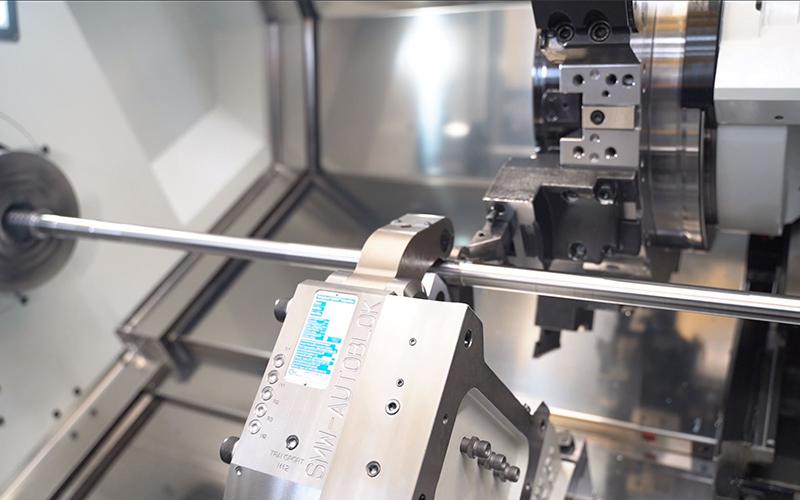

CMZ offers high flexibility to customise the machine you need. For instance, it is possible to configure the number of steady rests and how they are driven. For the TD models with the longest bed lengths it is possible to configure up to two steady rests bases, mounting one or two steadies per base. In case of mounting just one steady rest, it can be placed either on the left or on the right side of the base.

For the travelling steady application, a machine with one or two steady rest bases driven by servomotors is necessary. It is usually configured in conjunction with a hydraulically driven tailstock and sometimes the latter can be "displaced" in order to enable the steady rest to move really close to the tailstock.

Get in touch with us and we will assist you in the selection of the most suitable machine for the components you want to produce.

Discover all the programming tips with this free downloadable

This system gives a pressure up to 70bar, being able to select different pressures by M codes. It uses so called elementless filters that are a hybrid between centrifugal separators and liquid cyclones. This means that the system does not use any paper like other high-pressure systems and can filter…

Does your application require in-process measurement? CMZ offers an accessory that can help you with this challenge. This application is usually used in long series runs where the tool wear has to be adjusted without the need of manual input or in critical applications where the tolerances are tight.…

Normally several clampings would be needed to finish the parts, or in some cases very specific transfer machines could also be used, but the investment would be much higher. To allow this indexation and be able to machine the part completely in one clamping indexing chucks are the best solution. Not only…

With this configuration, customers can machine parts in the main-spindle with the tailstock engaged using the upper turret, while simultaneously machining parts in the sub-spindle with the lower turret. Working with a tailstock on a TTL or TTS is a very productive option because of the ability to work…

Our applications department can analyse in detail the process to be carried out and offer you a part study helping you to reduce cycle times.