The use of two tools compensates the cutting forces allowing you to machine further away from the chuck. This application is available for all our multiturret cnc lathes in the TX Series.

Balanced cutting is the process of simultaneously machining with two towers. The principle of this operation is based on balancing the machining forces of each tower.

When machining with a single tower, the machining force acts as a lever on the part and creates vibrations. However, when two towers machine at the same time, the mechanizing forces are cancelled out, allowing vibrations to be reduced and increasing the cantilever of the part.

Balanced cutting can be applied to both milling and lathing. In the case of lathing, machining advances can be increased by up to double.

This application of CNC lathes is highly useful in parts such as shafts or slender geometries. In the case of CMZ, the clients who use this process most are those who come from the automotive or capital goods sectors. An example of balanced cutting is roughing and semi-finishing of short shafts for gearboxes for forklift trucks.

Balanced cutting can be done with the CMZs TX series of lathes, both Y2 (2 towers) and Y3 (3 towers).

Discover all the programming tips with this free downloadable

This powerful 66mm bar capacity twin turret twin spindle CNC lathe can cut with 3 or even 4 tools simultaneously making the TTL a great machine for producing higher volumes of complex parts. Superimposed machining is made possible by a combination of sub-spindle axis movement in X and Z and 3 programming…

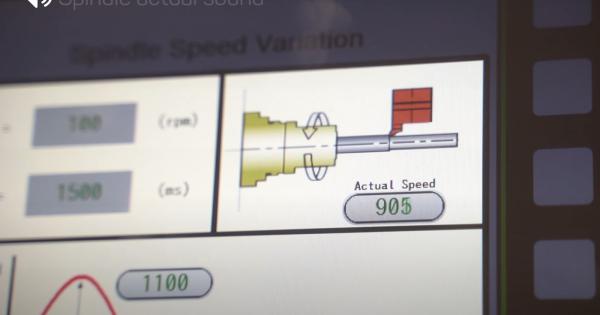

Chatter must be avoided at all costs. Chatter not only produces a poor surface finish on diameters but also seriously limits tool life. Long slender shafts, extended boring bars, thin walls and so on, can present real challenges. Spindle Speed Variation function allows the spindle speed to fluctuate…

Material is a considerable percentage in component cost. In order to avoid large material waste on the cut off, the blades are usually very thin and long, which often lead to vibrations and bad surface finish. The only solution is to reduce the tool overhang to minimise the effect; however, the…

When the geometry of the part allows it, it is even possible to cut with four tools at the same time performing a double balance cutting process. One of the turrets and the subspindle (TOOL 1+TOOL 2) will be programmed with superimpose function and the other turret will be programmed as a single trajectory…

Our applications department can analyse in detail the process to be carried out and offer you a part study helping you to reduce cycle times.