Chatter must be avoided at all costs. Chatter not only produces a poor surface finish on diameters but also seriously limits tool life. Long slender shafts, extended boring bars, thin walls and so on, can present real challenges.

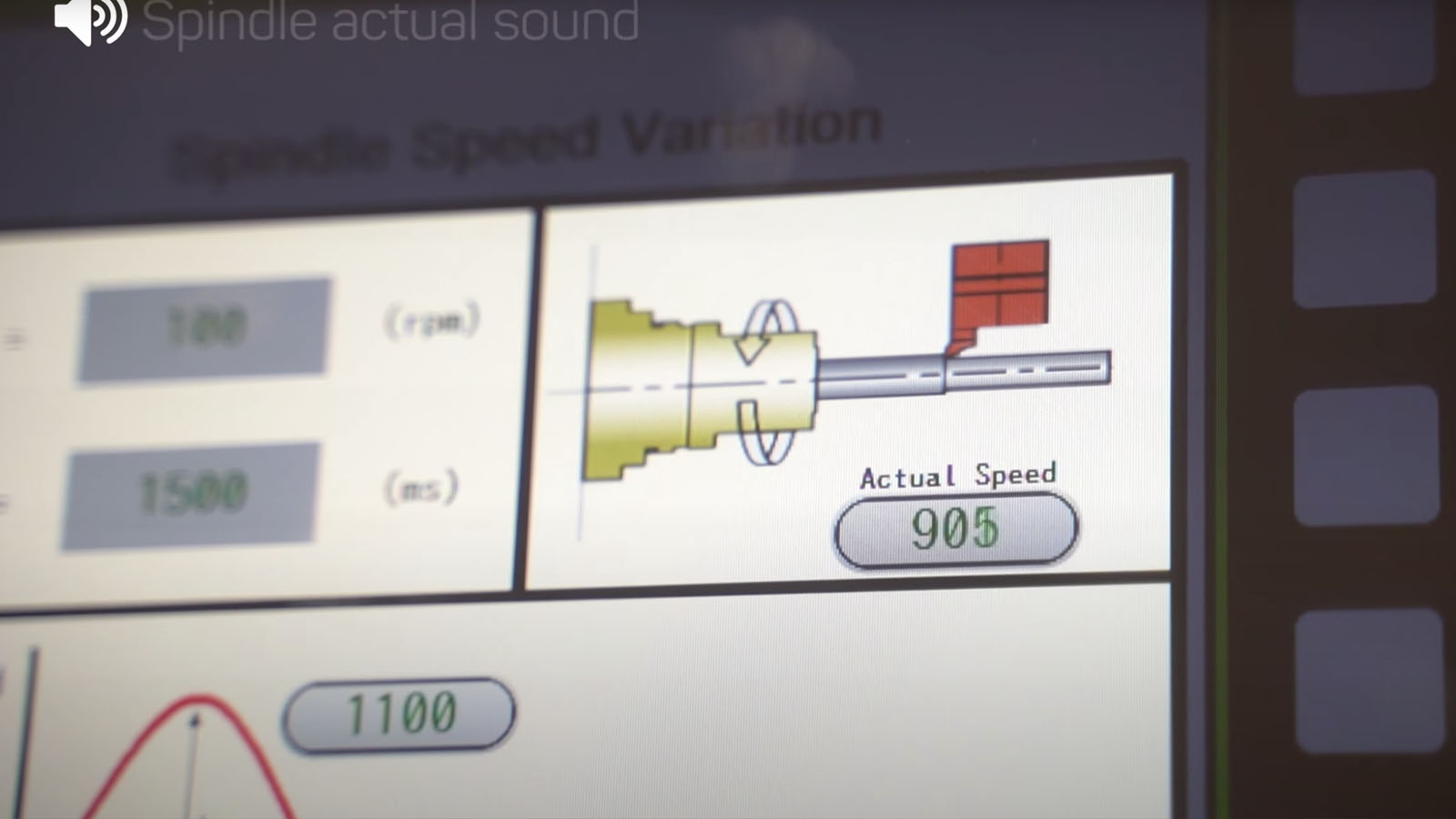

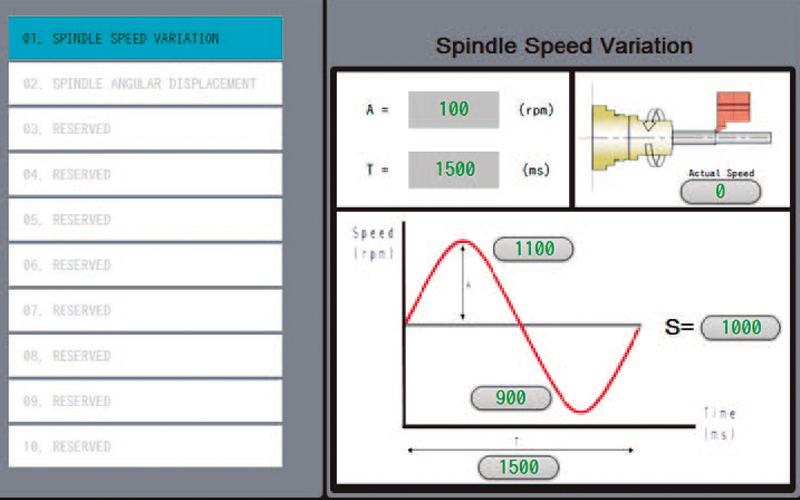

Spindle Speed Variation function allows the spindle speed to fluctuate within the period and amplitude of a sinusoidal curve which can be defined in a simple setup. With this function, very good results can be achieved in reducing chatter vibration.

All our TA, TD, and TTL series lathes CNC (from now on) are all equipped with SSV as standard.

Discover all the programming tips with this free downloadable

Material is a considerable percentage in component cost. In order to avoid large material waste on the cut off, the blades are usually very thin and long, which often lead to vibrations and bad surface finish. The only solution is to reduce the tool overhang to minimise the effect; however, the…

A solution to automate the process of machining shafts in your CNC lathe. Our GL20II gantry loader system combined with the WS700 workstocker for shafts allows you to leave you machines running unmanned. You can have several parts in each line up to 700mm. Controlling the robot is very easy and you…

One of the most critical aspects in many machining processes is chip formation. Long and entangled chips are formed mainly in turning operations due to constant cutting conditions. This issue requires changes in the process; such as modifying machining parameters or changing tools to get into a safer…

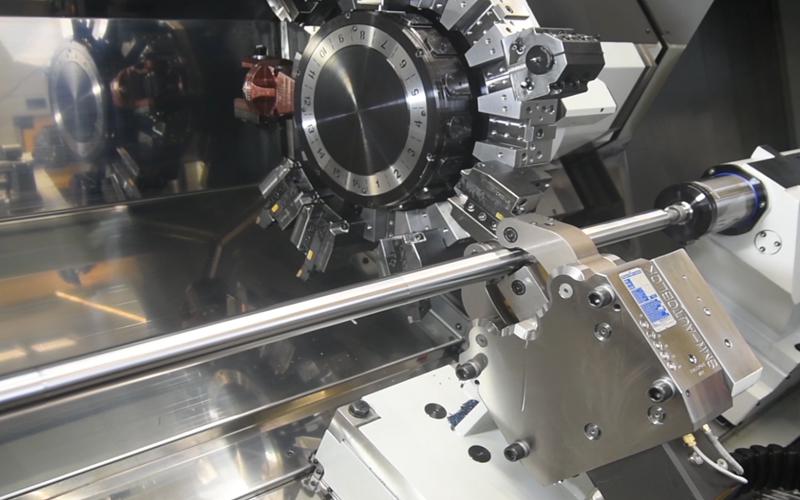

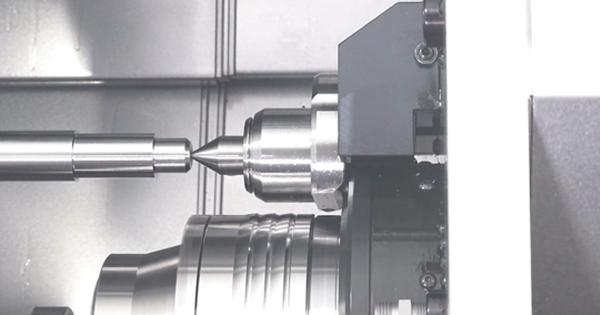

With this configuration, customers can machine parts in the main-spindle with the tailstock engaged using the upper turret, while simultaneously machining parts in the sub-spindle with the lower turret. Working with a tailstock on a TTL or TTS is a very productive option because of the ability to work…

Our applications department can analyse in detail the process to be carried out and offer you a part study helping you to reduce cycle times.