Those who work in the world of high precision know that accuracy is the order of the day. Every micron counts! Making the right choice when investing in equipment and machinery is vitally important for workshops specialised in bar turning. The market offers a wide variety of models and products: Nakamura WY 100, Citizen Miyano ANX 42, Biglia BMX 45, TTS Series, Nakamura WT 100, BNJ 42, B438… The offer is infinite, but what criteria should be taken into account when choosing the best ally for high precision machining?

There is a wide variety of options when choosing a machine for bar turning. Many factors influence the choice of one model or another: the brand, lead time, capacity, price... There are two aspects that should take priority over all the others: the technical characteristics and functions. These factors are the ones that mark the difference in terms of production rate and quality for companies dedicated to high production.

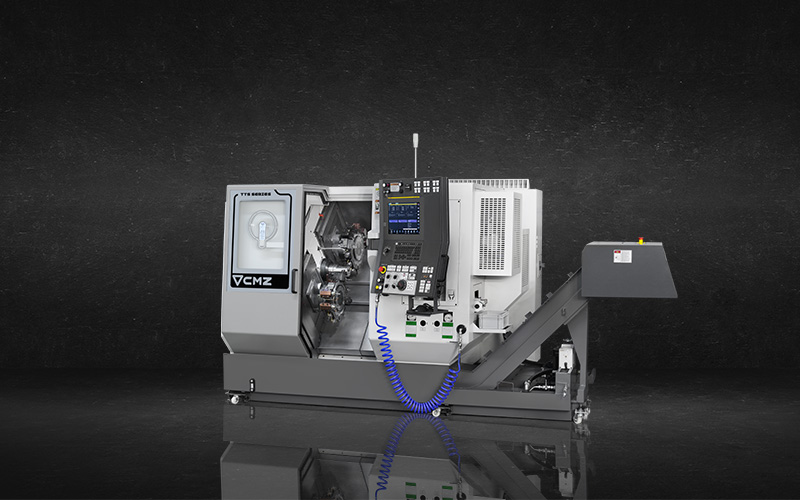

The TTS Series is part of CMZ's range of multi-turret machines and is the smallest machine in its current global product portfolio. It is a fixed head lathe competing with sliding head lathes and specifically designed for high production. It enables the production of highly complex precision parts. It is a safe bet for precision engineering companies that manufacture components for sectors like the aeronautic and automotive industries.

The range of choice couldn't be any wider: Nakamura WY 100, Citizen Miyano ANX 42, Biglia BMX 45, TTS Series, Nakamura WT 100, BNJ 42, B438… All these options are valid and have their strong and weak points. Objective data should take priority over any other aspect in sectors where profit margins are very tight and volumes very high. The X3 and Z3-axis movements provide CMZ's TTS Series with unique features. These are the main reasons why any company considering the purchase of a fixed head lathe for bar turning should choose it:

In addition to these functionalities the 24-position turrets in the TTS Series have an integrated motor for driven tools. The integrated spindles with synchronous motors reduce acceleration time by 50% so that, for example, the TTS-46 model reaches 5000 rpm in 1.75 seconds. Note also that the TTS Series offers multiple configurations: 1 turret/2 channels with Ø38 Ø46 Ø52 Ø66 bar capacity, 2 turrets/3 channels with Ø38 Ø46 Ø52 Ø66 bar capacity. The machine can be configured according to the production needs of each customer.

CMZ is a "rare beast" of machine tools. While large multinationals based in Asia compete in the market with thousands of employees, in CMZ over 500 people distributed over 8 production plants, 5 subsidiaries and the headquarters have taken the company's philosophy to heart and manufacture CNC lathes with care and dedication and painstaking attention to detail,

CMZ's business model, with manufacture entirely located in its production plants in Europe, is based on controlling the process from start to finish. To that end, over 80% of the components assembled in the lathes are manufactured in our own machining plants. By avoiding the import costs associated with de-localised production, CMZ has a larger margin for investing in top quality components.

The guarantee of a lathe manufacturer is always fundamental when purchasing a fixed head lathe for high production. For that reason, with the above-mentioned functions and technical characteristics, the TTS Series is a safe bet.