Discover this turning centre for high production. Next generation of 3 axis CNC machines. Multi-turret lathes.

TTS Series

Twin spindle lathe for parts made from bar

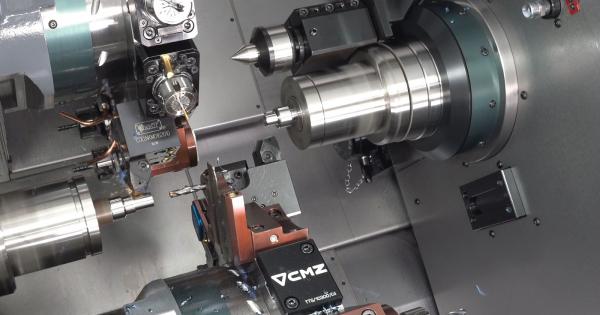

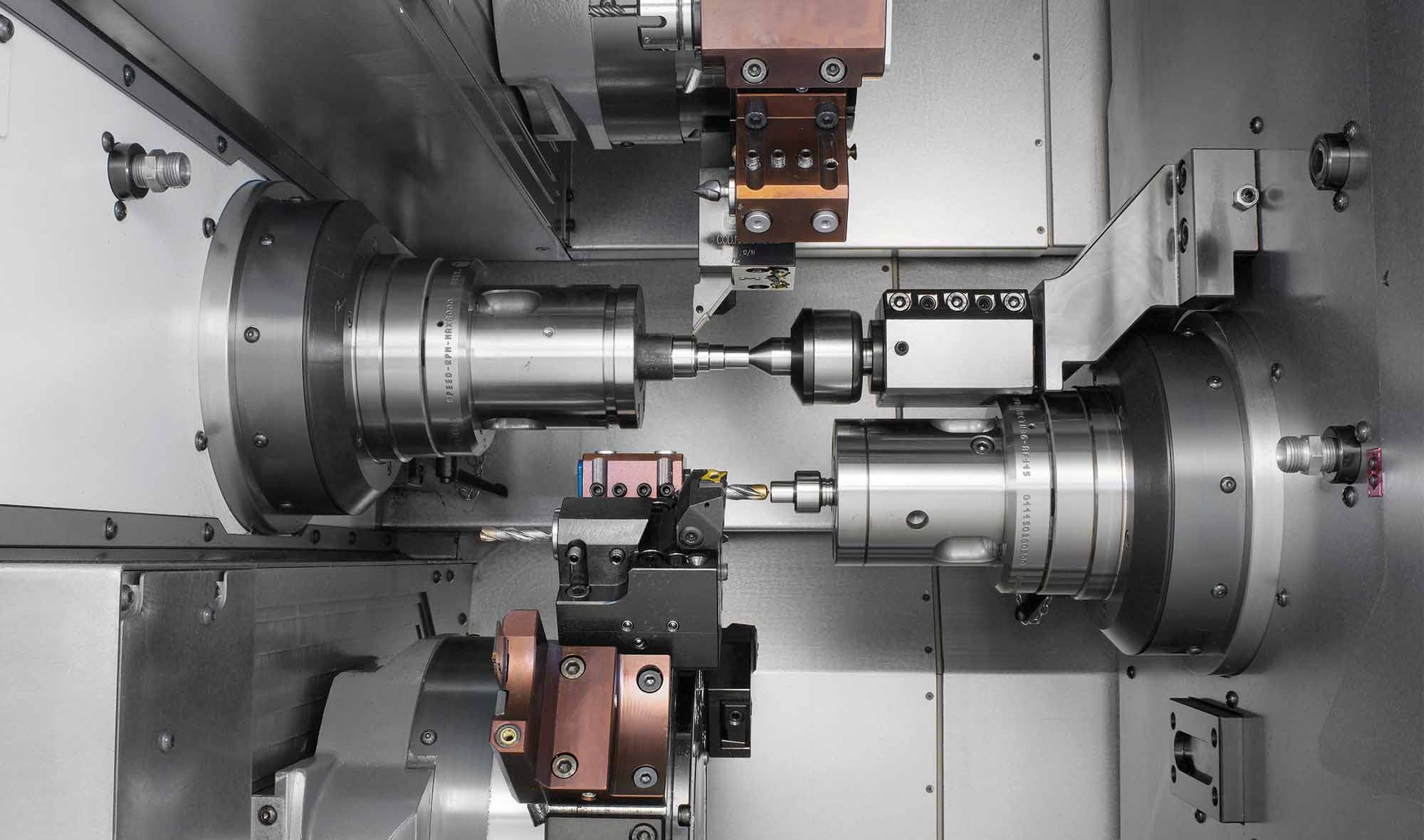

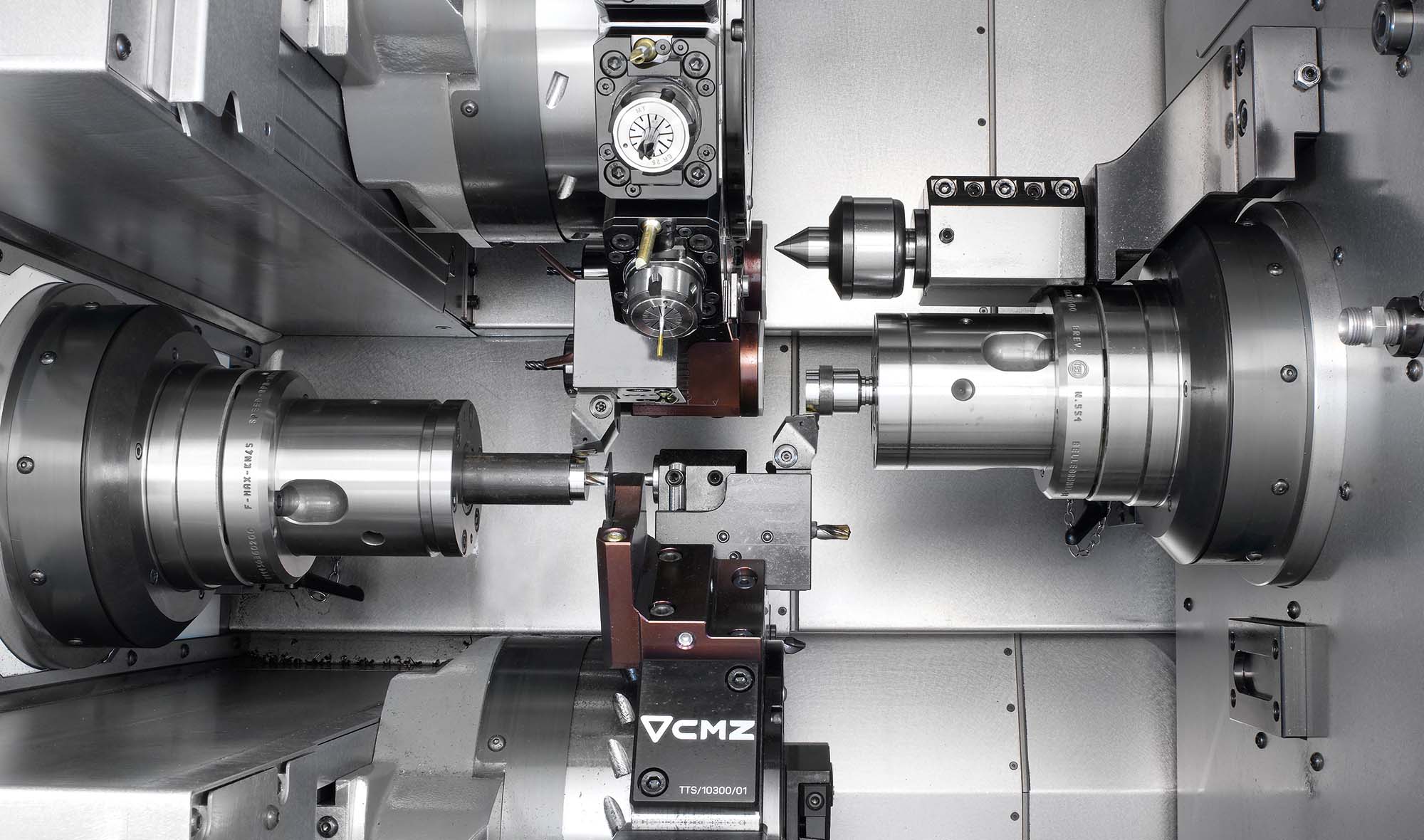

The TTS Series is the smallest lathe in the CMZ product range and part of our multi-turret range of turning centres. The TTS is ideal for machining complex mill-turn parts from bar. This is due to its accuracy, repeatability, and reliability, as well as powerful (13.2Kw, 26.8Nm) driven tools that are capable of running at 12,000rpm all day long. Both turrets are oil-cooled. All motors are direct drive (without belts).

The TTS has been specifically designed to significantly reduce cycle times and is capable of superimposed machining (cutting with 3 tools at once). Y-axis travel of +-31mm is available on both turrets. This machine is also much quicker to set compared to Swiss type machines. All this amounts to achieving an efficient production solution.

The X3 and Z3 axes on this twin spindle lathe for machining from bar allow multiple possibilities: work with the sub-spindle moved off centre and work with the tailstock, machine with two turrets on the same spindle, cut simultaneously with 3 tools (superimposed machining), or balanced cutting, Oscillation Cutting is available on both turrets and both spindles. A dual-spindle CNC lathe aimed at companies producing parts from bar.

Multiple configuration options

Twin spindle lathe TTS Series

TTS 38 / TTS 46 / TTS 52 / TTS 66 Models

1 turret, 2 channels

Max. bar diameters: Ø38 Ø46 Ø52 Ø66

2 Turrets, 3 Channels

Max. bar diameters: Ø38 Ø46 Ø52 Ø66

FUNCTIONALITIES

Discover the exclusive functionalities of this dual-spindle CNC lathe thanks to the movements in the X3 and Z3 axes

Tailstock: Operating simultaneously with sub-spindle (option)

One of the options of this fixed-headstock cnc lathe is the tailstock attached to the sub-spindle. The TTS allows the tailstock to be incorporated above or below the spindle. With this machine configuration, it is possible to machine between the chuck or the main chuck and the tailstock while finishing the part in the sub-spindle.

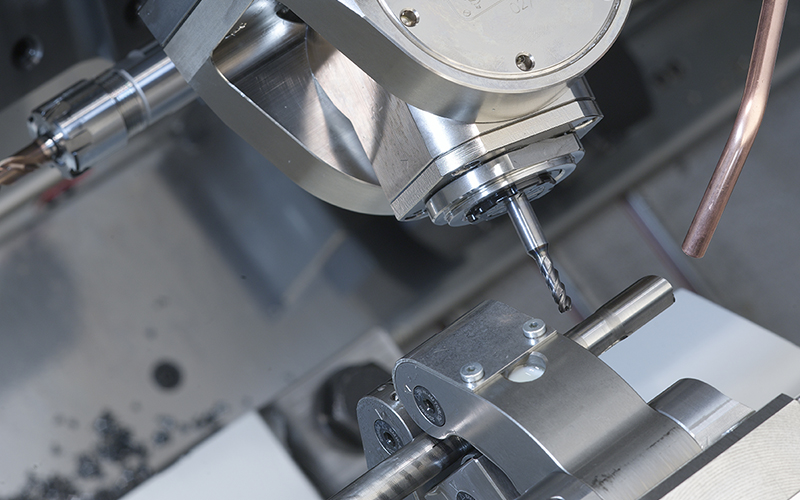

The TTS can work with 3 tools simultanously

This twin spindle lathe designed for bar turning has two turrets, although the CNC has 3 channels allowing 3 programs to be run simultaneously with their corresponding offsets. The sub-spindle (axes X3 and Z3) can work in the third channel of the CNC in a compound mode with the upper and lower turret. In this way, it is possible to place two tools in both turrets and machine with three tools simultaneously

Machining very long components

THE LINEAR MOVEMENT OF THE SUB-SPINDLE REDUCES INTERFERENCES

TTS SERIES VS OTHER DUAL-SPINDLE LATHES

Comparison of twin spindle lathes

Which is the best fixed head lathe for you?

TTL Series

Turning centre

- ø52 and ø66 Maximum bar diameter

- 35Kw 205Nm Spindles

- 220 mm ø Max. turning diameter

- 800 mm Distance between centre of spindles

- 2 Turrets and 3 channels* *3 tools work simultaneously

- 1 Turret and 2 Channels *2 tools work simultaneously

- Gantry Robot

- Tailstock

- With or withour Driven Tool (turrets)

- With or whitout Y axis in any turret

TTS Series

Dual-spindle CNC lathes

This Twin CNC Lathe for bar turning completes the TT range. It is the shortened version of TTL. It is designed for turning small parts and competes with sliding head lathes.

- ø38, ø46, ø52 and ø66 Maximum bar diameter

- 17Kw 66Nm Spindles

- 120 mm ø Max. turning diameter

- 638 mm Distance between centre of spindles

- 2 Turrets and 3 channels* *3 tools work simultaneously

- 1 Turret and 2 Channels *2 tools work simultaneously

- Gantry Robot

- Tailstock

- With or withour Driven Tool (turrets)

- With or whitout Y axis in any turret

Applications

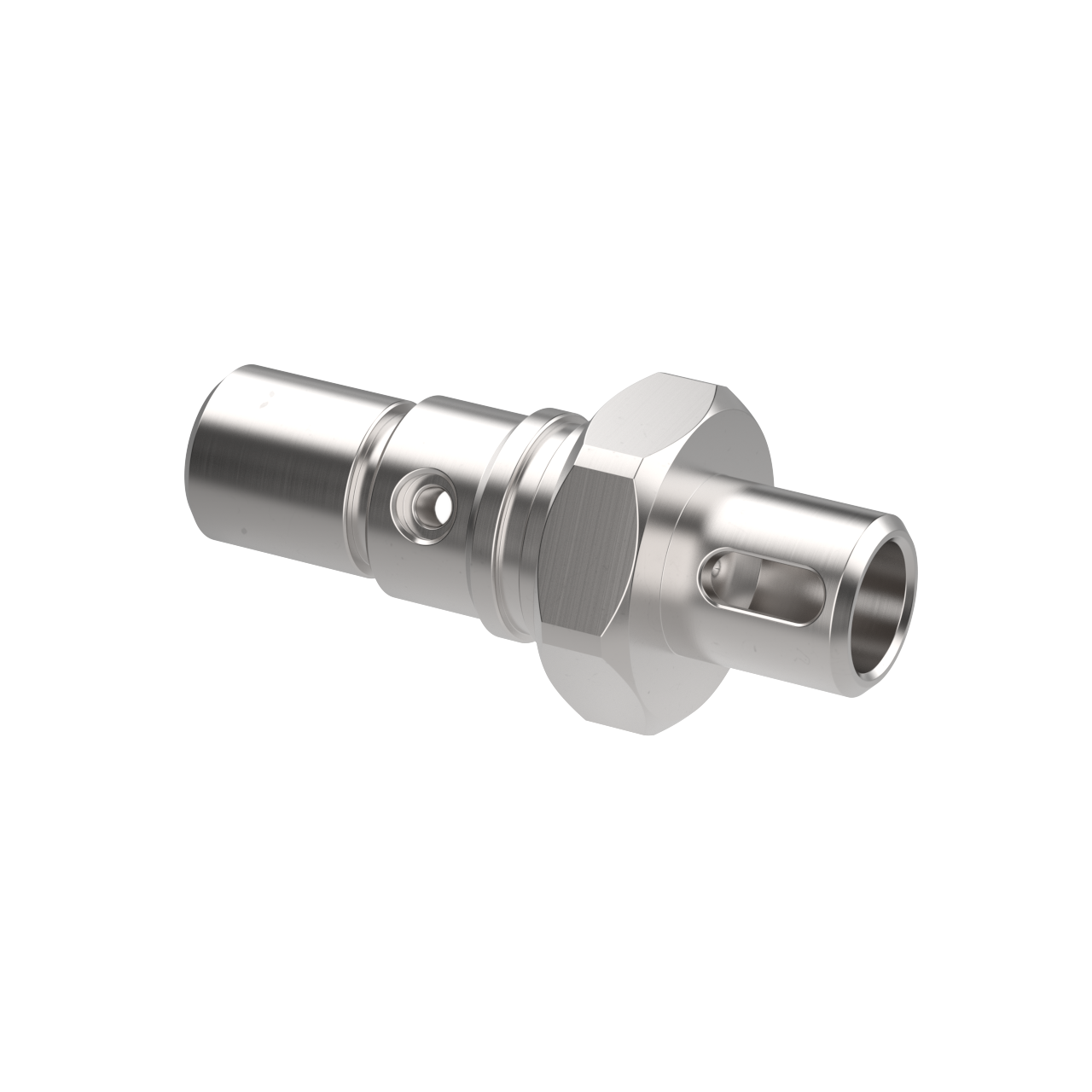

Examples of machined parts

Bushing

Connection pin

Male stud body

Punch

Demo connector

TTS CATALOGUE

The TTS is the new twin spindle CNC lathe in CMZ's range of multi-turret machines. Get to know it thoroughly!