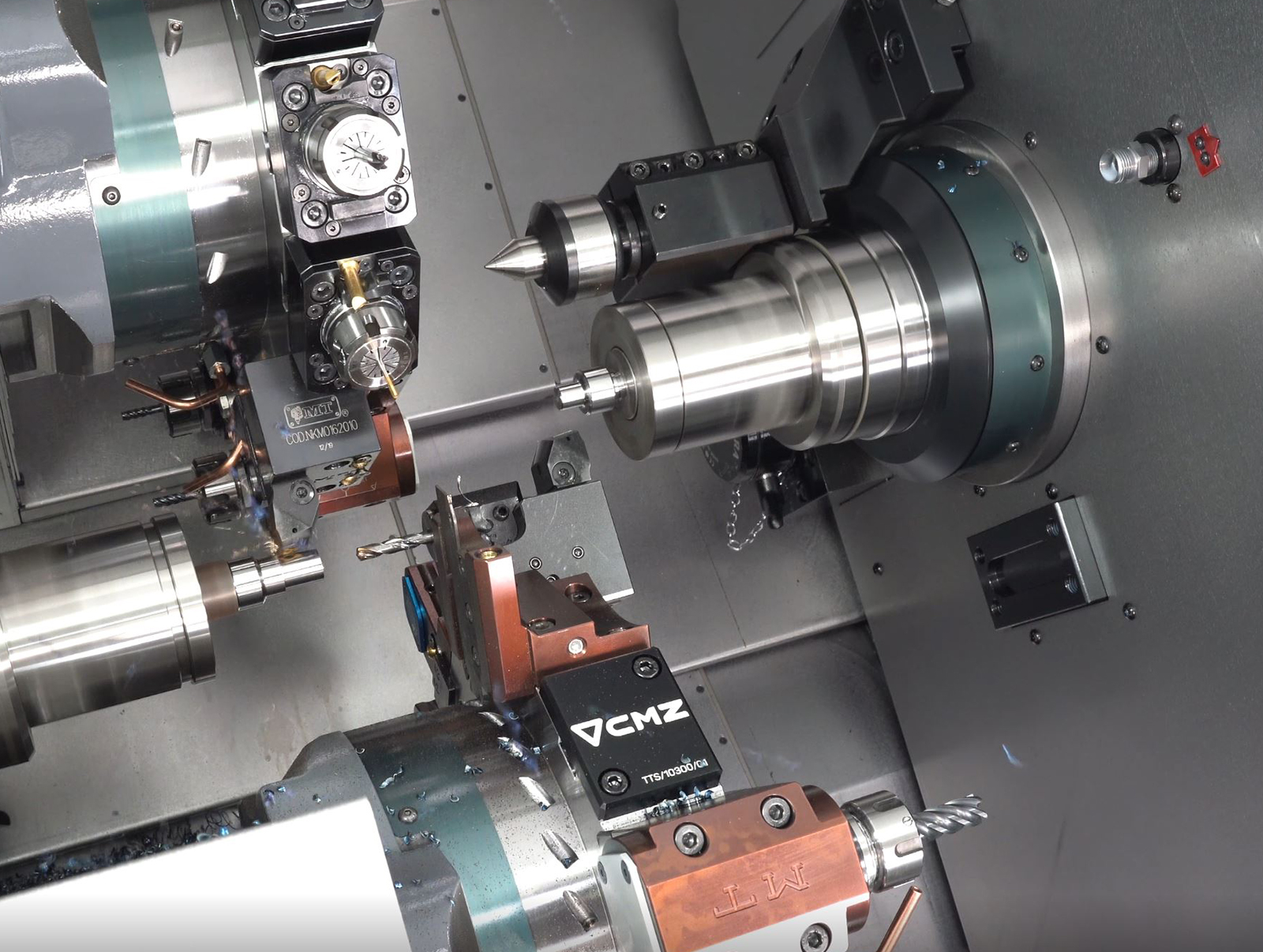

The TTS and TTL Series make up the multi-turret family of machines for bar work. This is the smallest lathe in the whole product range. Its precision and reliability guarantee the quality of this machine, used in industries such as the oil and gas, medical and general machining industries, with particular focus on bar turning.

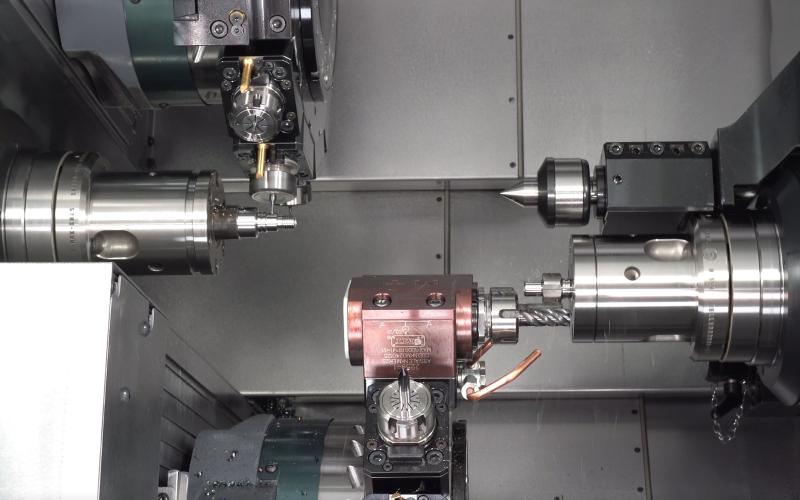

In the examples of use shown in the video, different lathe operations performed on this machine for bar turning are shown. They are all possible thanks to the technical specifications of this twin spindle lathe for bar turning and the features which the movements of the X3 and Y3 axes permit.

Main technical characteristics:

This document demonstrates schematically the different lathe operations performed on the TTS, showing the wide range of possibilities for this new CMZ Series and the utility of different options which may be added.

The sub-spindle moves both vertically and horizontally thanks to the movement of the X3 and Y3 axes. Thanks to this, the methods of use are as follows:

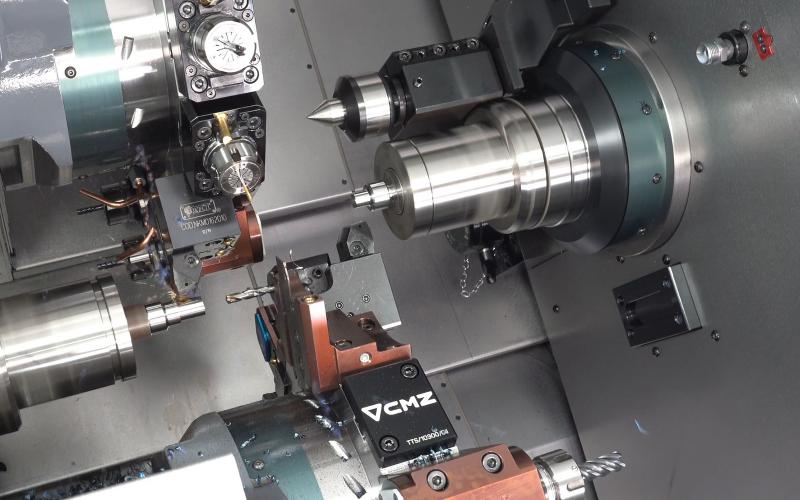

Companies dedicated to bar turning can optimise their cycle times and machining processes thanks to this multifunctional lathe. The dual spindle CNC lathe is the latest showpiece from CMZ to complete their range of multi-turret lathes. Bar work and lathe operations for making small parts require machines with a high degree of precision. The TTS has been designed under this key principle and is 100% geared towards satisfying the needs of those industries.

Optimising machining processes is a reality thanks to our new TTS twin spindle lathe.

Discover all the programming tips with this free downloadable

This powerful 66mm bar capacity twin turret twin spindle CNC lathe can cut with 3 or even 4 tools simultaneously making the TTL a great machine for producing higher volumes of complex parts. Superimposed machining is made possible by a combination of sub-spindle axis movement in X and Z and 3 programming…

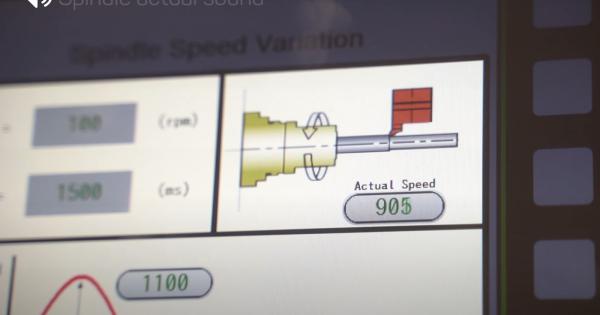

Chatter must be avoided at all costs. Chatter not only produces a poor surface finish on diameters but also seriously limits tool life. Long slender shafts, extended boring bars, thin walls and so on, can present real challenges. Spindle Speed Variation function allows the spindle speed to fluctuate…

Material is a considerable percentage in component cost. In order to avoid large material waste on the cut off, the blades are usually very thin and long, which often lead to vibrations and bad surface finish. The only solution is to reduce the tool overhang to minimise the effect; however, the…

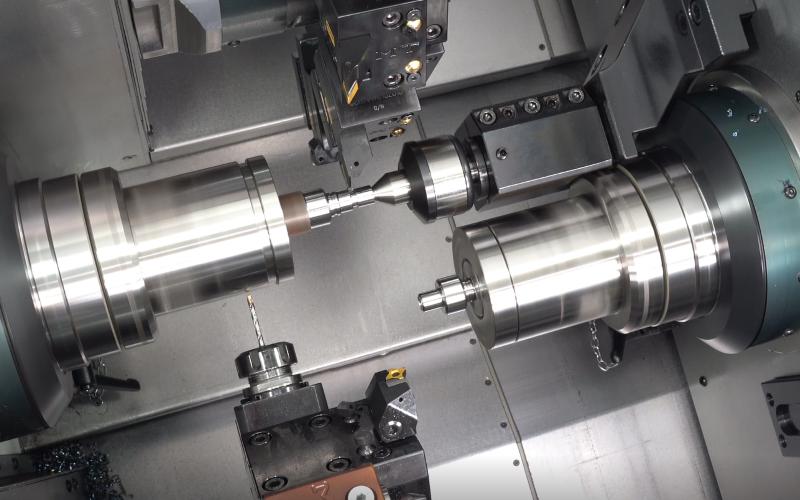

When the geometry of the part allows it, it is even possible to cut with four tools at the same time performing a double balance cutting process. One of the turrets and the subspindle (TOOL 1+TOOL 2) will be programmed with superimpose function and the other turret will be programmed as a single trajectory…

Our applications department can analyse in detail the process to be carried out and offer you a part study helping you to reduce cycle times.