Precitor is CMZ's new plant for machining high accuracy cylindrical parts and has more than 2,000m2 of useable space which is strictly temperature controlled (+-1º). This is where the spindle shafts for our driven tool holders are produced using a multi-turret lathe with tailstock. And thanks to its Gantry Robot Loader, we have managed to automate the process and save a great deal of cycle time.

There are several operations in the manufacturing process for spindle shafts. First of all, the part is turned, then coated (with a ceramic coating where the rotary unions go) and finally, it is ground. In this video, we specifically show the stage of machining the spindle shaft on a CNC turning centre from the TTL series.

The process involves the following stages:

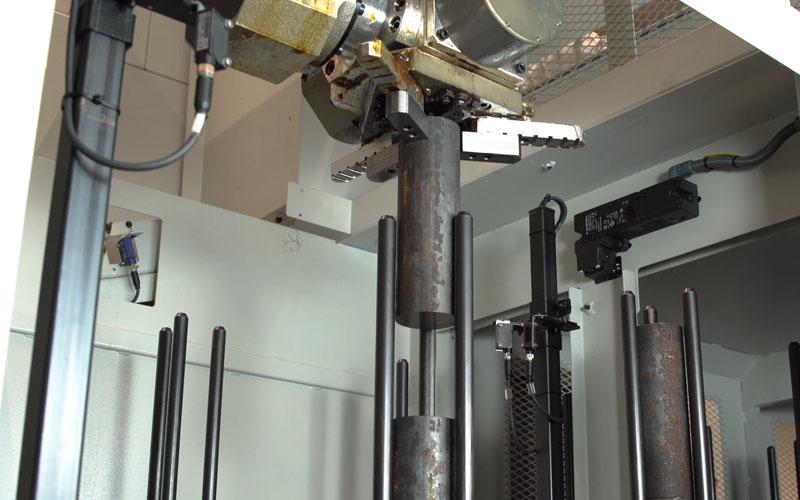

The gantry loader loads the raw material from the workstocker.

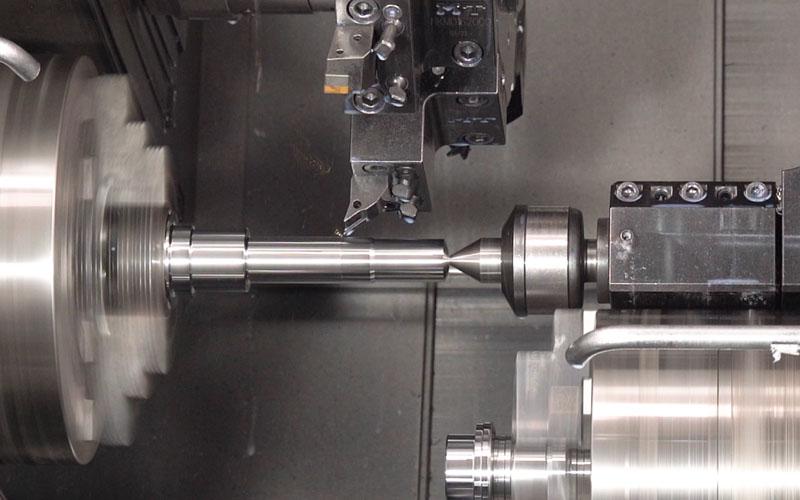

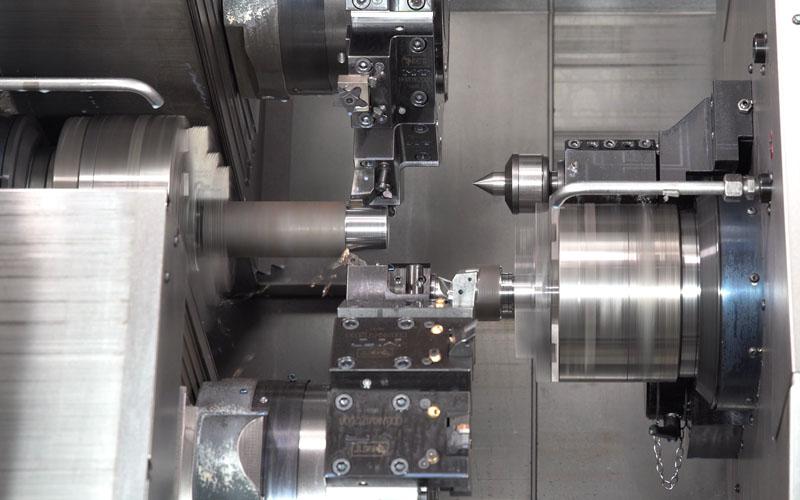

As the part is very long, it is turned using balanced cutting and at the same time is drilled on the sub-spindle.

The main and sub-spindles on CMZ lathes are mounted on roller bearings, which reduces vibration This means turning can be done away from the chuck face.

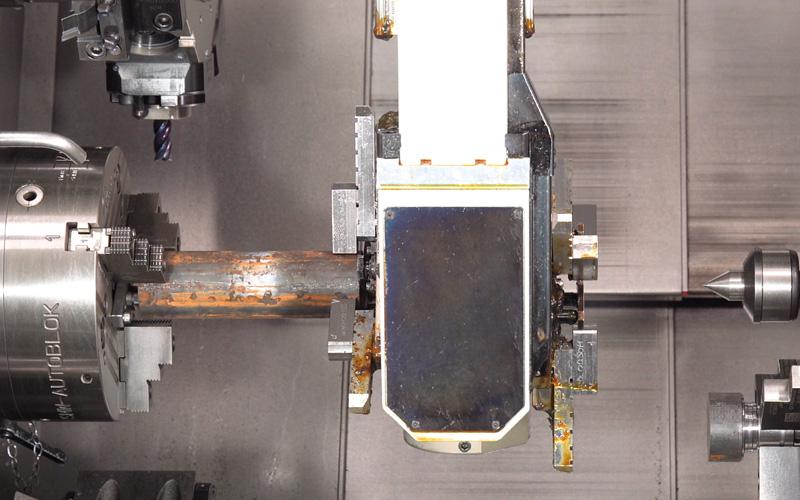

Using the tailstock, the finish pass is done between the chuck and tailstock while turning on the sub-spindle.

When the part is finished, it is taken to an unloading table where the operator has easy access. The Gantry Loader is an ideal option for automating the production process.

Find out about the entire process of machining a shaft on a multi-turret lathe using a tailstock and Gantry loader in this video:

This powerful 66mm bar capacity twin turret twin spindle CNC lathe can cut with 3 or even 4 tools simultaneously making the TTL a great machine for producing higher volumes of complex parts. Superimposed machining is made possible by a combination of sub-spindle axis movement in X and Z and 3 programming…

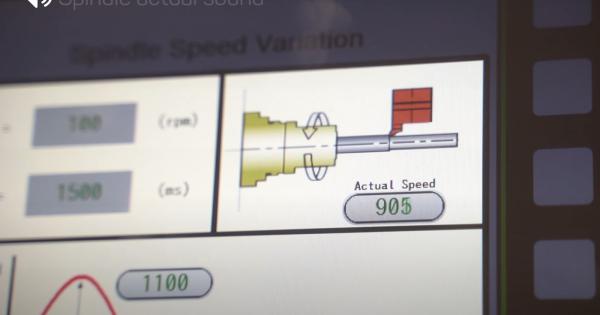

Chatter must be avoided at all costs. Chatter not only produces a poor surface finish on diameters but also seriously limits tool life. Long slender shafts, extended boring bars, thin walls and so on, can present real challenges. Spindle Speed Variation function allows the spindle speed to fluctuate…

Material is a considerable percentage in component cost. In order to avoid large material waste on the cut off, the blades are usually very thin and long, which often lead to vibrations and bad surface finish. The only solution is to reduce the tool overhang to minimise the effect; however, the…

When the geometry of the part allows it, it is even possible to cut with four tools at the same time performing a double balance cutting process. One of the turrets and the subspindle (TOOL 1+TOOL 2) will be programmed with superimpose function and the other turret will be programmed as a single trajectory…

Our applications department can analyse in detail the process to be carried out and offer you a part study helping you to reduce cycle times.