This time, we are in Neoprec, our machining plant for small and medium-sized parts which has 8,000 m2 of climate-controlled facilities. Here, there are three robotic cells which run fully automated.

In the following video we show you one of the three robotic cells we use to machine small, high precision parts in operation. The cell has a vertical five axes machining centre, a 3D Coordinate measuring machine (CMM), a parts washer and two robots.

The cell operates as follows:

This type of automated cell delivers high productivity, because the machine can work for 48 hours without human intervention. The cell also has a 3D CMM machine which measures 100% of the parts and automatically corrects the machine offsets. This ensures 100% valid parts and drastically improves precision because the offsets are updated for each part.

Discover the entire tool holder manufacturing process in the following video:

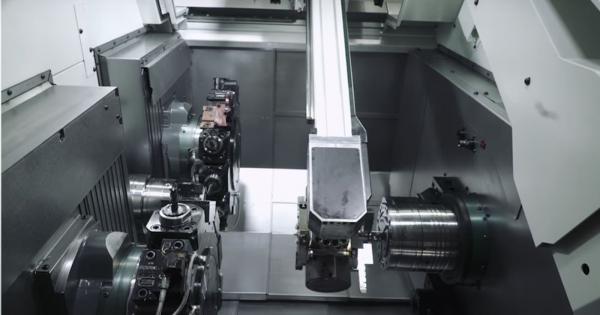

This video is a recording from one of CMZ's turning facilities in the recently renovated Precitor (Elorrio). Here you can see how Sergio, part of the team of operators who usually prepares one of our 12 CNC lathes, changes a TD-30-YS-800 + GL100 from one short run to another. You will see how the additional…

Process automation is crucial to increase productivity. Using bars as stock material is very common in turning world and although the use of barfeeders is extended, the automation gets more complicated when the parts are long because extraction systems are quite costly. CMZ has pneumatic parts catcher…

Every machining process can be a challenge in itself. With CMZ's recently expanded automation solutions for loading and unloading components, you will find the answer to improve the productivity of your process. The latest design of the Gantry Loader, the GL-100, has been developed by CMZ to automate…

This system is not limited to billets, CMZ manufacture gripper heads and workstockers both for billets and shafts. The combination of a barfeeder and Gantry Loader can be a very effective way to manage larger quantities of finished components. In this video, we show the process of a finished component…

Our applications department can analyse in detail the process to be carried out and offer you a part study helping you to reduce cycle times.