The acquisition of new CNC machinery for a machining workshop is a major decision that necessarily entails a considerable investment. Companies approach this process with a wide variety of options before them: the Nakamura WY 150, Citizen Miyano BNE, Biglia B465, Nakamura WT 150, CMZ TTL Series, Biglia B446, Nakamura WY 250, Nakamura WT 250… The array of possibilities is vast, but not all of them are equal. In this article we explain the features that make all the difference. The TTL Series has unprecedented functions and technical specifications.

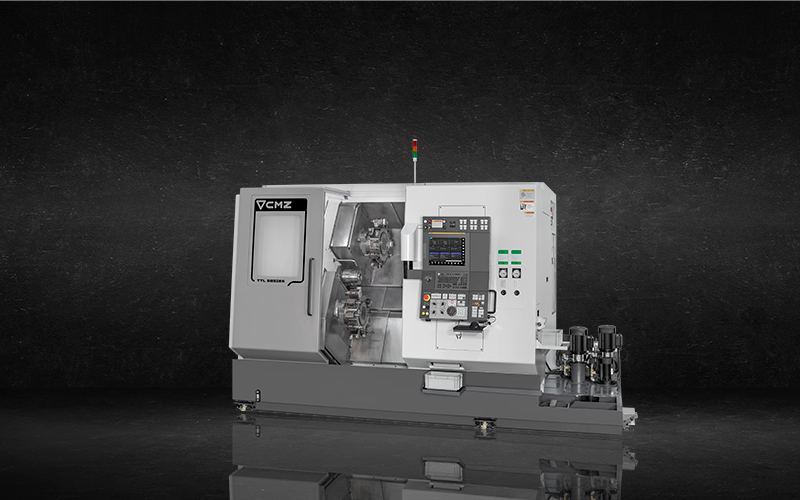

The TTL Series belongs to our range of multi-turret lathes, and is our largest machine in this specific category. This turning centre is a machine for high production and bar turning. Its most frequent users come from companies related to the world of automotive, aerospace, general machining..., companies that work with very demanding lead times and have a large volume of pieces to produce. Machining complex parts is made simpler thanks to the TTL's performance, accuracy, and reliability.

In comparison with other similar lathes, such as the Nakamura WY 150, Citizen Miyano BNE, Biglia B465, CMZ TTL Series, Nakamura WT 150, Biglia B446, Nakamura WY 250, or Nakamura WT 250, CMZ's TTL stands out due to the following features:

In an increasingly globalised and impersonal world, we are the "rare beast" of machine tools. A family business with an international presence, made up of over 450 people, which competes with large offshore multinationals with thousands of employees. In such an aggressive and hard-fought terrain, sometimes it is daring to opt for a business model like ours. We know that quality comes from having maximum control over each phase of the process of building our lathes. Anyone who buys from CMZ is getting a machine which:

Our expansion model doesn't just involve selling lathes in more and more countries, but also offering a good after-sales service. All of this is possible thanks to our aftersales department. Any customer who contacts CMZ is dealt with directly by the engineers from the Technical Assistance Service, without any non-technical intermediaries or operators.

If you are thinking of purchasing a turning centre, the TTL could be the machine for you. We hope that this technical and functional analysis will help you make the best decision 😉