Discover this turning centre for high production. Next generation of 3 axis CNC machines. Multi-turret lathes.

TTL SERIES

TURNING CENTRE FOR HIGH PRODUCTION

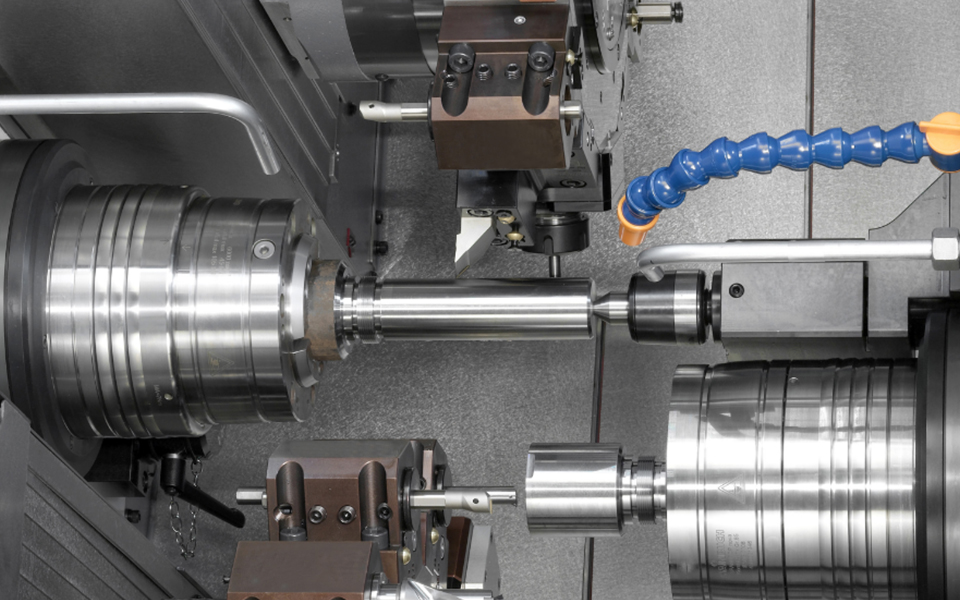

Precision turning companies work with very high volumes, tight lead times and very high precision. The high precision turning centre in the TTL Series is the largest machine in CMZ’s range of multi-turret machines. Especially indicated for machining complex parts, the TTL is a beltless turning centre with 8 integrated motors. Its motorised turret is oil cooled and the spindles reduce acceleration time by half. Movements in the X3 and Z3 axes permit unique functionalities:

- Tailstock (optional), enabling machining between the main spindle and tailstock while machining continues as normal in the sub-spindle.

- Work with 3 tools at a time (Superimposed machining).

- Machine longer parts: the large X3 axis travel moves the sub-spindle body away from centre line to reduce interferences.

The TTL Series is undoubtedly the best option for anyone looking for a high performance turning centre with maximum precision.

FUNCTIONALITIES

Discover the exclusive functionalities of this turning centre thanks to the movements on the X3 and Z3 axes

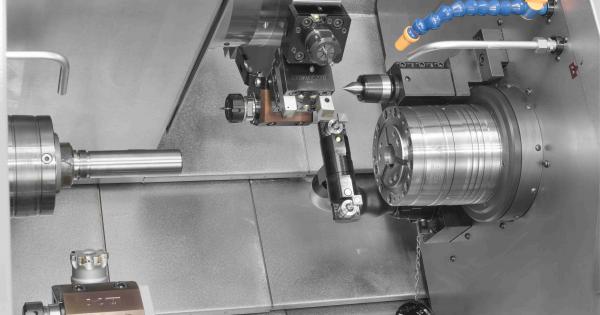

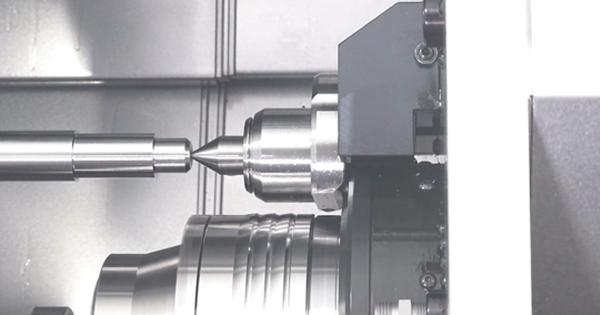

Simultaneous work with tailstock and sub-spindle

This turning centre has the option of adding a tailstock attached to the sub-spindle body. That arrangement enables machining between main spindle and tailstock while machining continues as normal in the sub-spindle, as shown in the photograph.

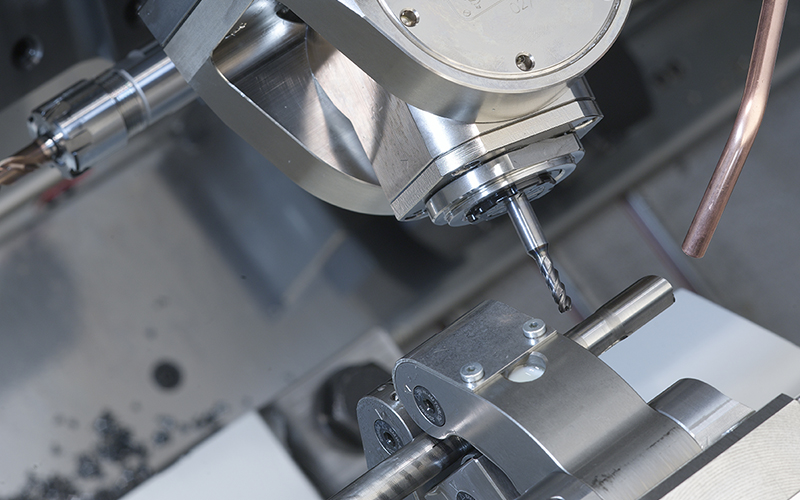

Superimposed machining with 3 tools simultaneously

The TTL turning centre has two turrets, but the CNC has 3 programming channels for executing 3 programs simultaneously, each of them with their own offsets. The sub-spindle (X3 and Z3 axes) can work in channel three of the CNC in a compound manner with both the upper and lower turret. That is to say, for Superimposed machining with three simultaneous tools, each tool can be placed in each turret (upper and lower).

MACHINE LONGER PARTS

The X3 travel of the sub-spindle body, away from centre line, reduces interferences

TTL SERIES VS OTHER TURNING CENTRES

AUTOMATION

AUTOMATE SHORT AND LONG BATCHES

ROBOT GL 20 II

CMZ’s Gantry loader GL 20II offers infinite automation solutions. With this Gantry Loader you can automate short and long batch runs. Its conversational programming system makes both handling and programming very easy. In addition, in order to maximise autonomy time, we have a wide variety of workstockers with large parts storage.

Here you can see our turning centre in the TTL Series equipped with a gantry loader Incorporating a gantry loader in your turning centre provides operators with great autonomy because part unloading can be automated. Unloading the finished part from the sub-spindle with our gantry GL2011 system means the turrets can continue working on the main spindle (reducing cycle time) and the finished part can be stacked individually avoiding contact.

TTL Series: Another Dimension

COMPARISON OF HIGH PRECISION LATHES

Which is the best turning centre for you?

TTL Series

Turning centre

- ø52 and ø66 Maximum bar diameter

- 35Kw 205Nm Spindles

- 220 mm ø Max. turning diameter

- 800 mm Distance between centre of spindles

- 2 Turrets and 3 channels* *3 tools work simultaneously

- 1 Turret and 2 Channels *2 tools work simultaneously

- Gantry Robot

- Tailstock

- With or withour Driven Tool (turrets)

- With or whitout Y axis in any turret

TTS Series

Dual-spindle CNC lathes

This Twin CNC Lathe for bar turning completes the TT range. It is the shortened version of TTL. It is designed for turning small parts and competes with sliding head lathes.

- ø38, ø46, ø52 and ø66 Maximum bar diameter

- 17Kw 66Nm Spindles

- 120 mm ø Max. turning diameter

- 638 mm Distance between centre of spindles

- 2 Turrets and 3 channels* *3 tools work simultaneously

- 1 Turret and 2 Channels *2 tools work simultaneously

- Gantry Robot

- Tailstock

- With or withour Driven Tool (turrets)

- With or whitout Y axis in any turret

APPLICATIONS

EXAMPLES OF MACHINING

Hood

Bushing

Drive shaft

Drive shaft

Toolholder body

Toolholder body

TTL CATALOGUE AVAILABLE NOW

Discover the TTL, the new generation of turning centres. Find out all about it!